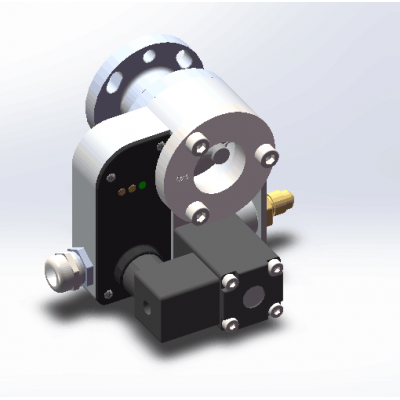

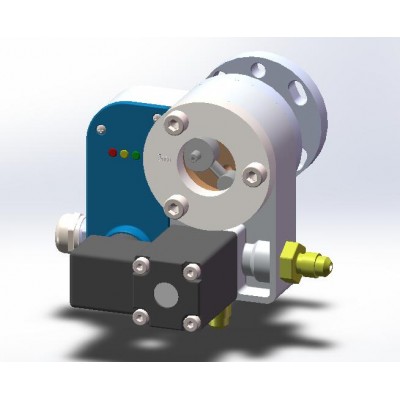

Basically, the oil level regulators used to control the oil level of each compressor crankcase via the balanced control device. It is manufactured with the extension which will be assembled directly to the compressors where the oil view glass is widely found. The Oil Level Regulator is generally installed between the line of suction and the oil receiver. Above the crankcase oil strain, it maintains the differential pressure in the oil vessel.

Are you looking to purchase Oil level regulator? If so then it is essential to hire the best company. It is quite difficult to choose the reliable company because there are massive numbers of companies is available to choose from. There are many factors to consider before choosing the company such as the quality, service, price, customer reviews, experience, and reputation among the clients. As well as choose the company who provide discounts on their products which can aid you to save money.

Buy Quality Regulator

The reliable company will provide high-quality oil level regulator product to the customers at the reasonable price. The skilled and experienced experts will provide the regulator as per the customer needs. It ensures appropriate crankcase oil level automatically in engines and stationery. By the reliable and safe oil level, the consumption will decrease and engine life will be extended. The regulator is easy and simple to install as well as it included adjustment control of level. Below mentioned are the features of the Oil level regulator.

- It has an automatic level regulator which use to maintain proper crankcase level of oil

- Eliminates common manual oil

- It has visible sight galls

- Low-level switch for warning

- Long life

- Resistant brass and many others

Benefits of installing Oil Level Regulator

The following are the benefits of installing a regulator

- Manual oil filling and checking

- It saves up to 50 percent in consumption of oil

- Maintains most favorable engine oil level

- Simple and easy to install

- Very simple to understand

- It will work with the flow meter

Follow us on social media

https://www.facebook.com/Goldar-1366567946755504/

https://plus.google.com/u/0/117255158380966255010